SPC Flooring is a high-quality resilient flooring that has made its place in the market through its nonpareil quality and remarkable features.If you decide to install a reliable flooring in your homes, Stone Polymer Composite - SPC flooring is one of the best option.

What is SPC flooring made of ?

It is made up of limestone, PVC resin and various stabilizers, and it is not only the trendiest option but is perfectly in your budget. Its comfort factor and the ease of maintenance makes it one of the most popularly chosen flooring type today!

Is SPC flooring toxic ?

Carsem Floor's SPC Flooring is non-toxic and free from formaldehyde, completely safe flooring covering materials for both residential and public environment.

It does not contain heavy metals, phthalate, methanol, and other harmful substances. Carsem Floor has got Floorscore, Greenguard Gold Level, Reach Certifications which are the most professional and authoritative certificates in the world. What's more important, SPC luxury vinyl flooring is very durable, easy to maintain, and very affordable.

Since you may be installing SPC flooring for the first time, this detail guide on what to expect from start to finish of flooring installation will walk you through the whole process.

If you are planning to D.I.Y your SPC flooring, always remember to consult with your supplier if you have any doubts, especially on details like:

1. Types of adhesive suitable for your flooring

2. Proper way to handle and store new flooring during installation (damage caused due to improper handling and storing normally does not get covered by warranty)

3. Review your warranty and confirm you have selected the proper flooring for your intended use.

4. Types of SPC Flooring underlayment to be used

5. Is your existing floor suitable for installation or must it be removed?

Preparing for Installation, get ready for the Right Tools And Materials. You'll need:

Double-sided mallet

Tapping block

Utility knife

SPC flooring cutter

Knee pads

Quarter-inch spacers

A pencil

Flooring pull bar

Measuring tape

A level

Chalk line reel

Carpenter's square

Prepare The Sub-floor

The first step on your to-do list before installation should be to check the sub-floor. Generally speaking, the thickness of SPC flooring is thinner than other lock system flooring such as laminate flooring, Click LVT, Hardwood flooring, engineered flooring, WPC flooring etc, so the requirements for ground flatness are higher. We recommend self-leveling to ensure the best condition of sub-floor. Make sure the sub-floor is clean, dry, smooth, flat and leveling, free from oil, paint, dust, grease, wax, chemical substances, mold and mildew.

Measure The Room

Calculate how many boxes of PVC vinyl SPC flooring you'll need for the project (8%-10% extra flooring is recommended because of installation loss).

Measure the length and width of the space.

Divide the area by square feet printed on the box.

Allow Time For Acclimation

Stack SPC LVT flooring boxes in the room where the flooring will be installed. Open the ends, let the boxes sit for 48 hours. The 48 hours will allow the flooring to adjust to the room’s temperature, which should be between 65-85 F. After 48 hours, the flooring will be better able to resist buckling and gaping as time goes by.

Installing SPC flooring

Click-lock SPC Flooring installation is the easiest for first timers who wish to go for D.I.Y. This method is sometimes known as floating method.

To apply click-lock or floating method, your SPC plank flooring must come with the long and short side design. So both planks can be click together and form a firm grip. You may also need to measure and cut off any extra length to fit in your area. It is advisable for you to start off your first plank from one corner of the room. Check out the step-by-step floating/ click-lock SPC flooring installation here.

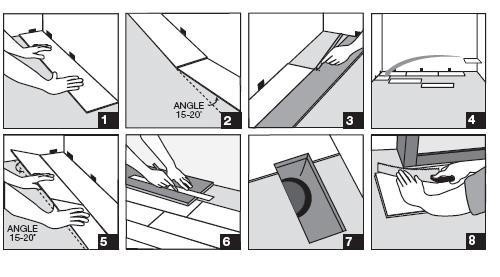

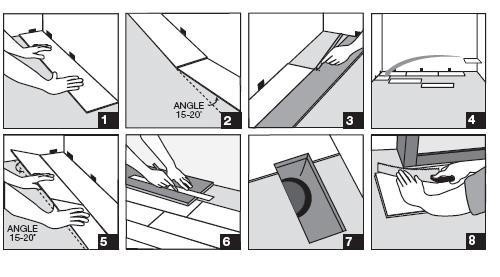

1. Insert the B plank convexly into the existing groove and lock it flat.

2. After the flattening, the distance between the B and the C tiles is about 2-3 mm into a parallel line.

3. Lift the A and B plank at the same time (about 45 degrees from the ground).

4. Push the surface of the B towards the C until they locked together.

5. Press the A and B down with the palm of your hand, do not force the floor too hard.

6. After the assembly is completed, the floor is flat and seamless. If the floor is uneven or has gaps, you need to lift them gently. The angle is locked, and the floor will be leveled automatically after being fastened.

Does SPC flooring expand ?

SPC Flooring is waterproof luxury SPC vinyl flooring, however, it is still have expanding & shrinking rate during high and low temperatures.

Make sure you leave a space for expansion of at least 2mm when fitting the side of plank against the wall. Below is Carsem Floor's SPC Flooring dimentional stability result in 80 degree with 6 hours of Chamber testing :

Test method: EN ISO 10582:2012 & with reference to ISO 23999:2008

Heating temperature: 80℃

Heating time: 6h

Lab environmental condition: 23±2℃, 50±5%RH

Test result: Test Item | Test Result | Requirement | Conclusion |

Dimensional change (%) | Manufacturing direction: 0.23 | ≤0.25 | Pass |

Across-manufacturing direction: 0.08 |

Curling (mm) | 0.0 | / | / |

How to cut SPC flooring?

Although SPC Flooring is high density rigid core LVT, cutting SPC flooring is super easy. Before installation, you have prepared installation tools which includes utility knife, SPC flooring cutter, pencil and measuring tape, that's enough.

Do not ever try to use a hammer or tapping block as this may cause damage to the click connection as resilient SPC vinyl flooring thickness is thinner, what you can do to ensure good locking is to press down gently with your palm.

SPC Flooring FINISHING

Once finish with the installation, maintain the surrounding moisture content and temperature for 48 hours. This will help stabilize the newly installed flooring and improve durability. If you hired professional installer, you will need to do a proper final inspection to make sure every corner are firmly installed.

If you have extra rigid SPC flooring planks or tiles left after installation, you may save them up and use it for any repair work in the future.

How to clean SPC vinyl flooring ?

Cleaning SPC flooring after installation, and sweeping the dirt and dust. Check out our waterproof SPC flooring maintenance advice for various tips on better taking care and maintaining your SPC flooring.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

Română

Čeština

Монгол

қазақ

हिन्दी

Kiswahili

Slovenčina

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

اردو

বাংলা

Afrikaans

සිංහල

Oʻzbekcha

latviešu

Aymara

Български

Hausa

Kurdî

Afaan Oromoo

Runasimi

Sesotho

Wikang Tagalog

isiXhosa

isiZulu